1.前言

本文提供一种基于CAPL控制数控电源的方法,其实现原理是CAPL中调用RS232,发送SCPI指令与数控电源通信。

理论上,本文适用于串口通信的数控电源或其他串口设备。

2.开发环境

2.1硬件环境

数控电源KORAD KA3005P,CANcaseXL

2.2软件环境

CANoe 9.0,串口调试助手

3.参考资料

KA系列标准通信协议_百度文库 https://wenku.baidu.com/view/6adf09f1294ac850ad02de80d4d8d15abe230039.html

CANoe DEMO:File-Sample Configurations-IO HIL-RS232,这里是个使用RS232的DEMO

4.测试SCPI指令

将数控电源连上PC,注意,虽然是USB接口,但是数控电源内部虚拟了串口,可以在设备管理器中发现。

用串口助手打开电源的串口,设置波特率为9600(这里测试任何一个波特率都可以,不知为什么)。

然后以ASCII的方式发送指令。

这里测试的目的主要是为了验证通信。

具体的指令可以根据文档描述测试一下,这里就不细说了。

5.建立CANoe工程

创建个合适的工程,建立CAPL NODE,DBC,以及PANEL

2.2软件环境

CANoe 9.0,串口调试助手

3.参考资料

KA系列标准通信协议_百度文库 https://wenku.baidu.com/view/6adf09f1294ac850ad02de80d4d8d15abe230039.html

CANoe DEMO:File-Sample Configurations-IO HIL-RS232,这里是个使用RS232的DEMO

4.测试SCPI指令

将数控电源连上PC,注意,虽然是USB接口,但是数控电源内部虚拟了串口,可以在设备管理器中发现。

用串口助手打开电源的串口,设置波特率为9600(这里测试任何一个波特率都可以,不知为什么)。

然后以ASCII的方式发送指令。

这里测试的目的主要是为了验证通信。

具体的指令可以根据文档描述测试一下,这里就不细说了。

5.建立CANoe工程

创建个合适的工程,建立CAPL NODE,DBC,以及PANEL

6.编辑CAPL代码

以下代码参考了Demo

6.编辑CAPL代码

以下代码参考了Demo

2.2软件环境

CANoe 9.0,串口调试助手

3.参考资料

KA系列标准通信协议_百度文库 https://wenku.baidu.com/view/6adf09f1294ac850ad02de80d4d8d15abe230039.html

CANoe DEMO:File-Sample Configurations-IO HIL-RS232,这里是个使用RS232的DEMO

4.测试SCPI指令

将数控电源连上PC,注意,虽然是USB接口,但是数控电源内部虚拟了串口,可以在设备管理器中发现。

用串口助手打开电源的串口,设置波特率为9600(这里测试任何一个波特率都可以,不知为什么)。

然后以ASCII的方式发送指令。

这里测试的目的主要是为了验证通信。

具体的指令可以根据文档描述测试一下,这里就不细说了。

5.建立CANoe工程

创建个合适的工程,建立CAPL NODE,DBC,以及PANEL

2.2软件环境

CANoe 9.0,串口调试助手

3.参考资料

KA系列标准通信协议_百度文库 https://wenku.baidu.com/view/6adf09f1294ac850ad02de80d4d8d15abe230039.html

CANoe DEMO:File-Sample Configurations-IO HIL-RS232,这里是个使用RS232的DEMO

4.测试SCPI指令

将数控电源连上PC,注意,虽然是USB接口,但是数控电源内部虚拟了串口,可以在设备管理器中发现。

用串口助手打开电源的串口,设置波特率为9600(这里测试任何一个波特率都可以,不知为什么)。

然后以ASCII的方式发送指令。

这里测试的目的主要是为了验证通信。

具体的指令可以根据文档描述测试一下,这里就不细说了。

5.建立CANoe工程

创建个合适的工程,建立CAPL NODE,DBC,以及PANEL

6.编辑CAPL代码

以下代码参考了Demo

6.编辑CAPL代码

以下代码参考了Demo

/*@!Encoding:936*/

includes

{

}

variables

{

// GLOBAL

const int kBUFFER_SIZE = 1000;

const int kINFO = 1;

const int kWARN = 2;

const int kERROR = 3;

const int kHANDSHAKE_DISABLED = 0;

const int kHANDSHAKE_RTSCTS = 33;

// define for dp serial port com9

const dword port = 9;

const dword baudrate = 9600;

const dword dataBits = 8;

const dword stopBits = 1;

const dword parity = 0;//0:none 1:even 0:odd

// data is copied from callback buffer to gReceiverBuffer (collects data)

byte gReceiverCallbackBuffer[kBUFFER_SIZE];

byte gReceivedBuffer[kBUFFER_SIZE];

dword gReceivedIndex= 0;

// state variable

byte gSending = 0;

byte gGetValueSt = 0;

byte gSetValueSt = 0;

msTimer t100ms;

msTimer t20ms;

}

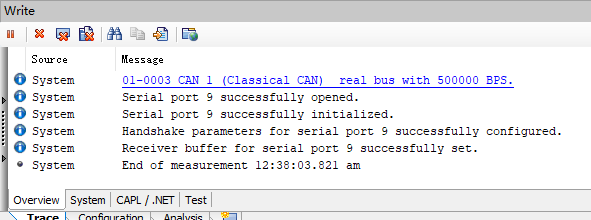

on preStart

{

InitSerialPort();

}

on start

{

setTimer(t100ms,100);

}

//RS232 Init

InitSerialPort()

{

// close serial port (port may have changed, former port shall not remain open)

if(Rs232Close(port)!=1)

writeLineEx(0,kERROR,"An error occurred during closing of the serial port %d.", port);

// set state (close aborts all open requests)

gSending = 0;

// open the serial port (comes up with Windows defaults)

if(Rs232Open(port)==1)

writeLineEx(0,kINFO, "Serial port %d successfully opened.", port);

else

writeLineEx(0,kERROR,"An error occurred during opening of the serial port %d.", port);

// configure the serial port

// - just take the panel content

if(Rs232Configure(port,baudrate,dataBits,stopBits,parity)==1)

writeLineEx(0,kINFO, "Serial port %d successfully initialized.", port);

else

writeLineEx(0,kERROR,"An error occurred during initialization of the serial port %d.", port);

// port, handshake, xonLim, xoffLim, xonChar, xoffChar, writeTimeout

// without last timeout parameter: use default timeout

// for transmission of small amounts of data one may not need to use handshake !

// e.g. 33 for RTS/CTS as second parameter for large volumes of data, 0 for small volumes

if(Rs232SetHandshake(port, kHANDSHAKE_DISABLED, 0, 0, 0, 0))

writeLineEx(0,kINFO, "Handshake parameters for serial port %d successfully configured.", port);

else

writeLineEx(0,kERROR,"An error occurred during the serial port %d configuration of handshake parameters.", port);

// set buffer for reception (otherwise callback would not work)

if(Rs232Receive(port, gReceiverCallbackBuffer, kBUFFER_SIZE))

writeLineEx(0,kINFO, "Receiver buffer for serial port %d successfully set.", port);

else

writeLineEx(0,kERROR,"An error occurred during setting the receiver buffer for serial port %d.", port);

}

//RS232 Call back

RS232OnReceive( dword port, byte buffer[], dword number )

{

dword i;

for(i=0;i=5)

{

DP_DataRecevied(gReceivedBuffer,gReceivedIndex);

gReceivedIndex=0;

}

}

}

//RS232 Call back

RS232OnSend( dword port, byte buffer[], dword number )

{

// set state

gSending = 0;

//writeLineEx(0,kINFO,"Transmission of %d bytes from port %d completed !", number, port);

}

//RS232 Call back

RS232OnError( dword port, dword errorFlags )

{

// set state

gSending = 0;

writeLineEx(0,kERROR,"Error handler called with error code %d !", errorFlags);

if ( errorFlags & 1 )

writeLineEx(0,1,"%d informs of send error",errorFlags);

if ( errorFlags & 2 )

writeLineEx(0,1,"%d informs of receive error",errorFlags);

if ( errorFlags & 4 )

writeLineEx(0,1,"%d informs of frame error",errorFlags);

if ( errorFlags & 8 )

writeLineEx(0,1,"%d informs of parity error",errorFlags);

if ( errorFlags & 16 )

writeLineEx(0,1,"%d informs of overrun error",errorFlags);

if ( errorFlags & 32 )

writeLineEx(0,1,"%d informs of receiver overrun error",errorFlags);

if ( errorFlags & 64 )

writeLineEx(0,1,"%d informs of break state",errorFlags);

if ( errorFlags & 128 )

writeLineEx(0,1,"%d informs of send timeout error",errorFlags);

}

CopyBuffer( byte destBuffer[], dword destOffset, byte srcBuffer[], dword srcNumber )

{

dword i;

for (i=0; i3000)

writeLineEx(0,kERROR,"Voltage too high! ");

else

{

buf[i++]=(byte)(vol/1000)+0x30;

vol%=1000;

buf[i++]=(byte)(vol/100)+0x30;

vol%=100;

buf[i++]='.';

buf[i++]=(byte)(vol/10)+0x30;

buf[i++]=(byte)(vol%10)+0x30;

DP_Send(buf, i);

}

}

DP_SetCurrent(float data)

{

char str[7]="ISET1:";

char buf[100];

word vol=0;

byte i;

for(i=0; i<6; i++)

{

buf[i]=str[i];

}

vol = (word)(data*1000);

if(vol>5000)

writeLineEx(0,kERROR,"Current too high! ");

else

{

buf[i++]=(byte)(vol/1000)+0x30;

vol%=1000;

buf[i++]='.';

buf[i++]=(byte)(vol/100)+0x30;

vol%=100;

buf[i++]=(byte)(vol/10)+0x30;

buf[i++]=(byte)(vol%10)+0x30;

DP_Send(buf, i);

}

}

DP_DataRecevied(byte buffer[], dword len)

{

switch(gGetValueSt)

{

case 0:

putValue(Env_GetVoltage,AtoF(buffer,len));

gGetValueSt=1;

break;

case 1:

putValue(Env_GetCurrent,AtoF(buffer,len));

gGetValueSt=0;

break;

default:

break;

}

}

float AtoF(byte buffer[], dword len)

{

double getData;

dword i;

byte flag;

dword per;

getData = 0;//static

per=1;//static

flag=0;//static

for(i=0; i

7.测试

8.总结

(1)CANoe十分强大,可以干很多事情,本文中的方法也只是众多控制数控电源方式中的一种,本人未开发过基于CANoe的自动化测试设备,也并不清楚并不清楚商业上是如何实现的。

(2)DEMO很有参考价值,不会的可以找DEMO参考

(3)他节点可以通过调用dbc中定义的环境变量,来获取或者设置电源的电压电流

(4)win10微软拼音在360浏览器编辑此贴,打字会抽风

8.总结

(1)CANoe十分强大,可以干很多事情,本文中的方法也只是众多控制数控电源方式中的一种,本人未开发过基于CANoe的自动化测试设备,也并不清楚并不清楚商业上是如何实现的。

(2)DEMO很有参考价值,不会的可以找DEMO参考

(3)他节点可以通过调用dbc中定义的环境变量,来获取或者设置电源的电压电流

(4)win10微软拼音在360浏览器编辑此贴,打字会抽风