本人模式识别小硕一枚,目前帝都某校研一在读。寒假自己用opencv做了一个对PCB板的好坏的检测,拿出来和大家一起学习讨论,这篇博文也是我在CSDN上发表的第一篇文章,欢迎各路大神指导。

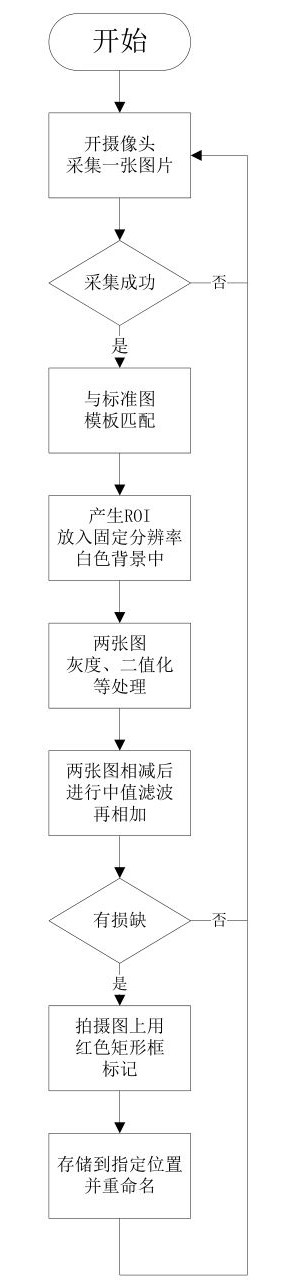

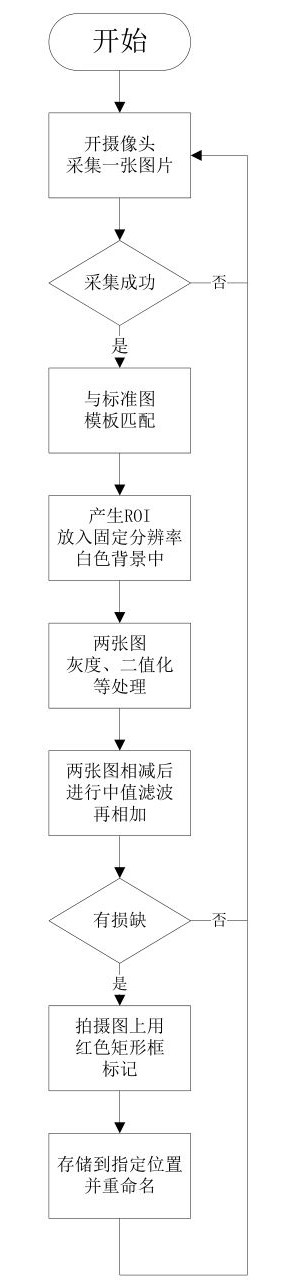

基本思想是通过定焦的工业摄像头,对放置于卡槽中的PCB进行拍摄并取ROI,与标准的PCB图片进行模板匹配,两者二值化后相减并中值滤波,在缺损处用红 {MOD}矩形标出,最后只命名输出缺损PCB图片。

为了给大家更好的演示,我将程序改为直接读取图片。

程序如下:

基本思想是通过定焦的工业摄像头,对放置于卡槽中的PCB进行拍摄并取ROI,与标准的PCB图片进行模板匹配,两者二值化后相减并中值滤波,在缺损处用红 {MOD}矩形标出,最后只命名输出缺损PCB图片。

为了给大家更好的演示,我将程序改为直接读取图片。

程序如下:

(可能有些杂乱,本人水平还需提高)

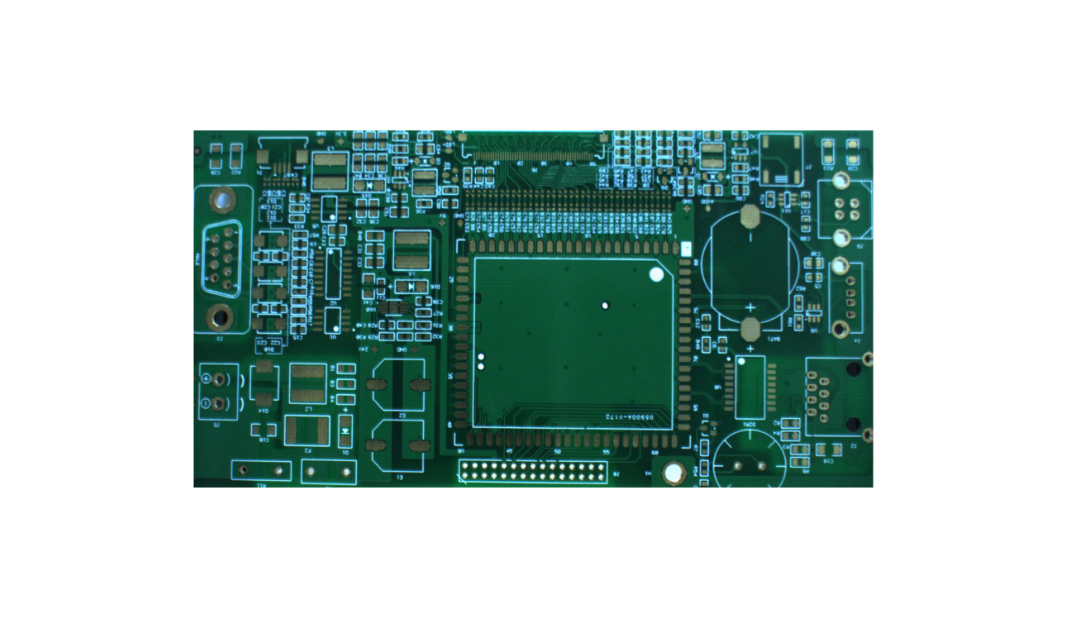

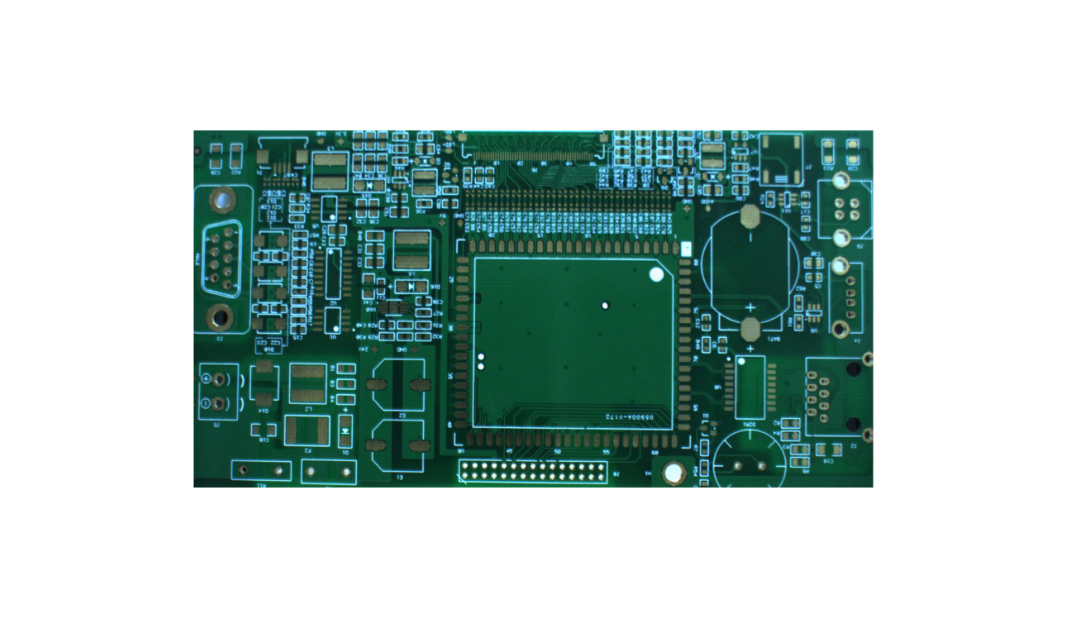

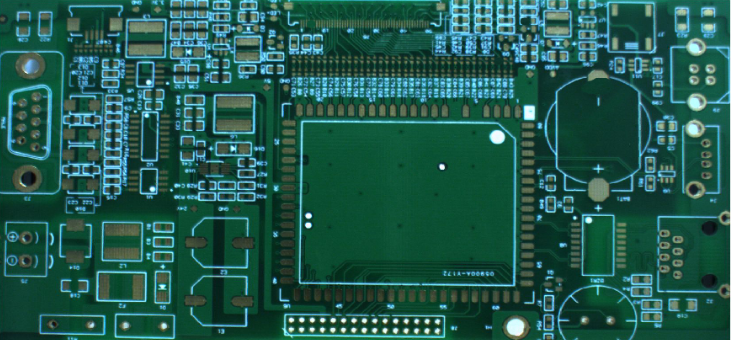

【完好无损的PCB】

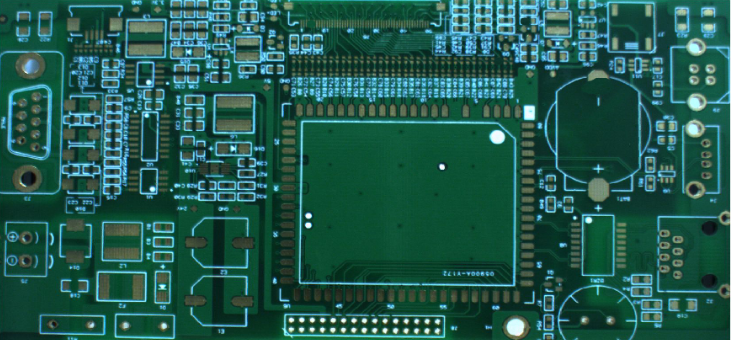

【有缺损的PCB】(焊盘缺失或缺损)

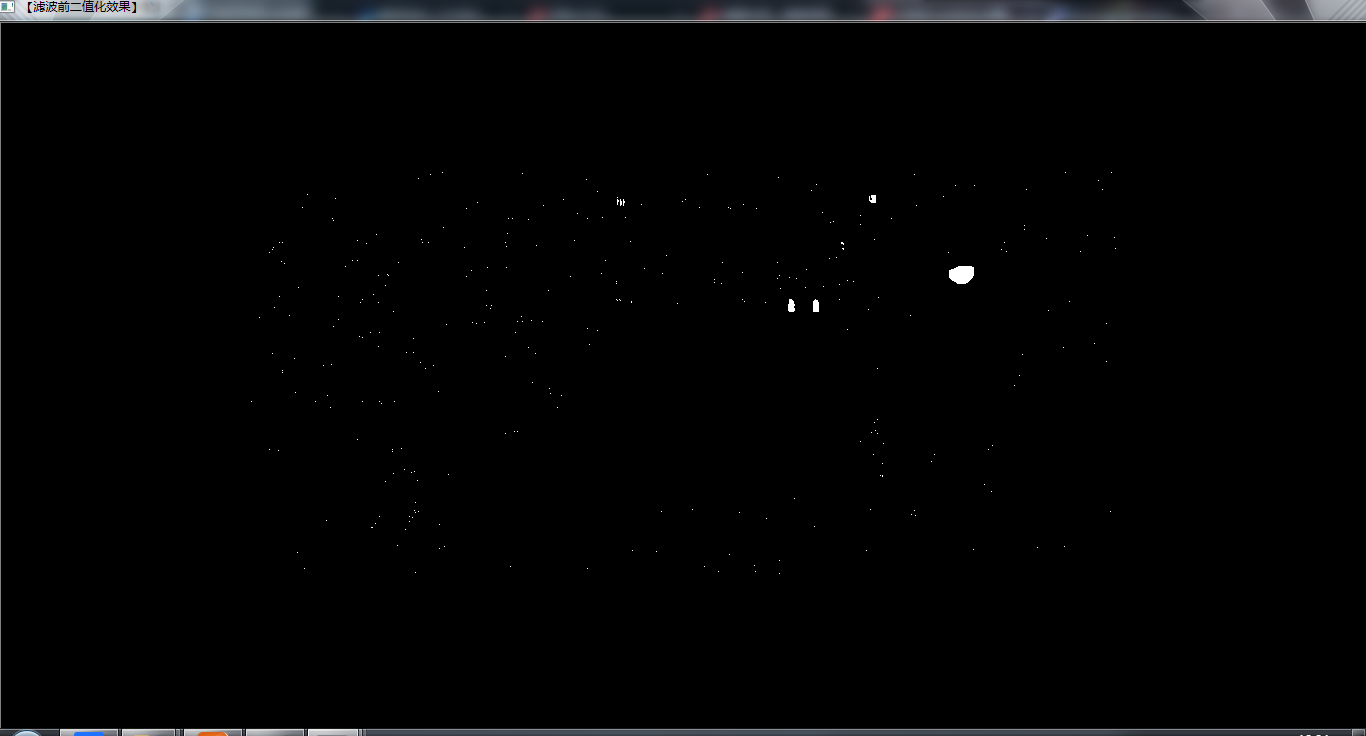

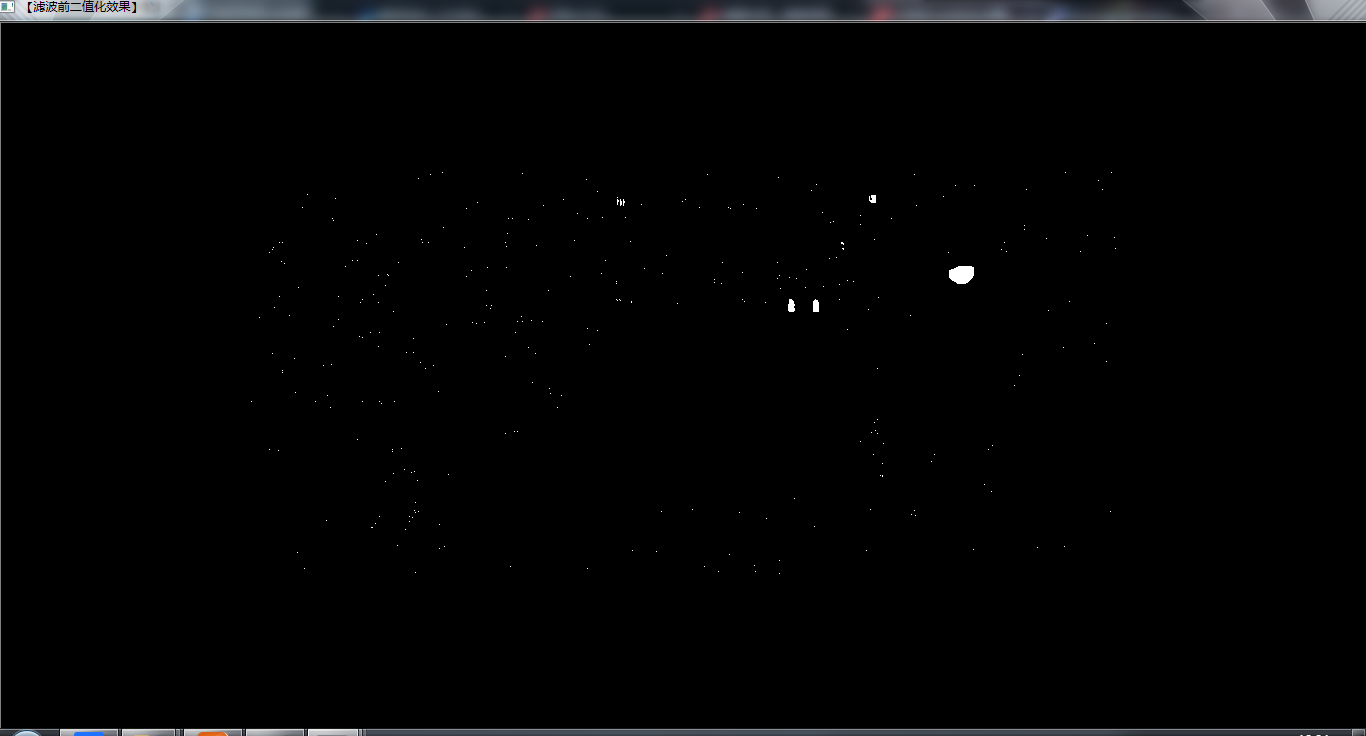

【处理后未滤波的图片】

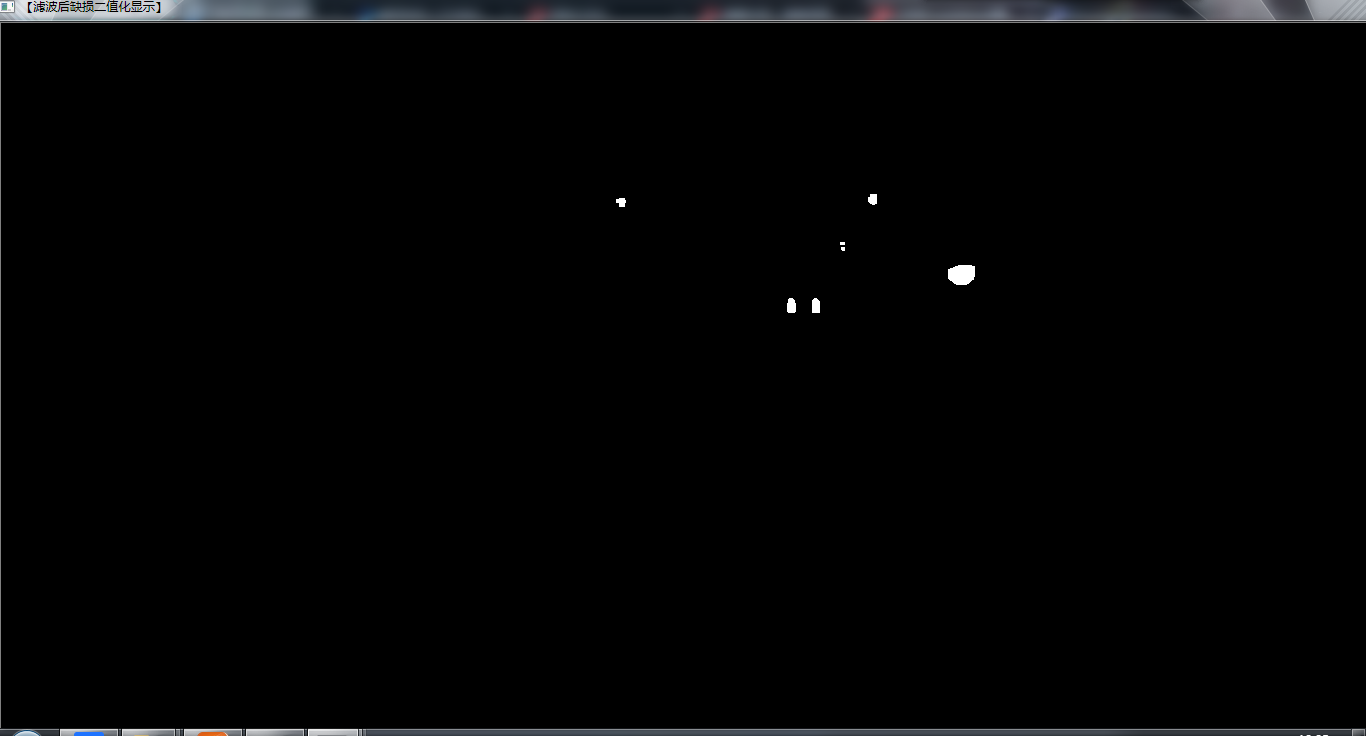

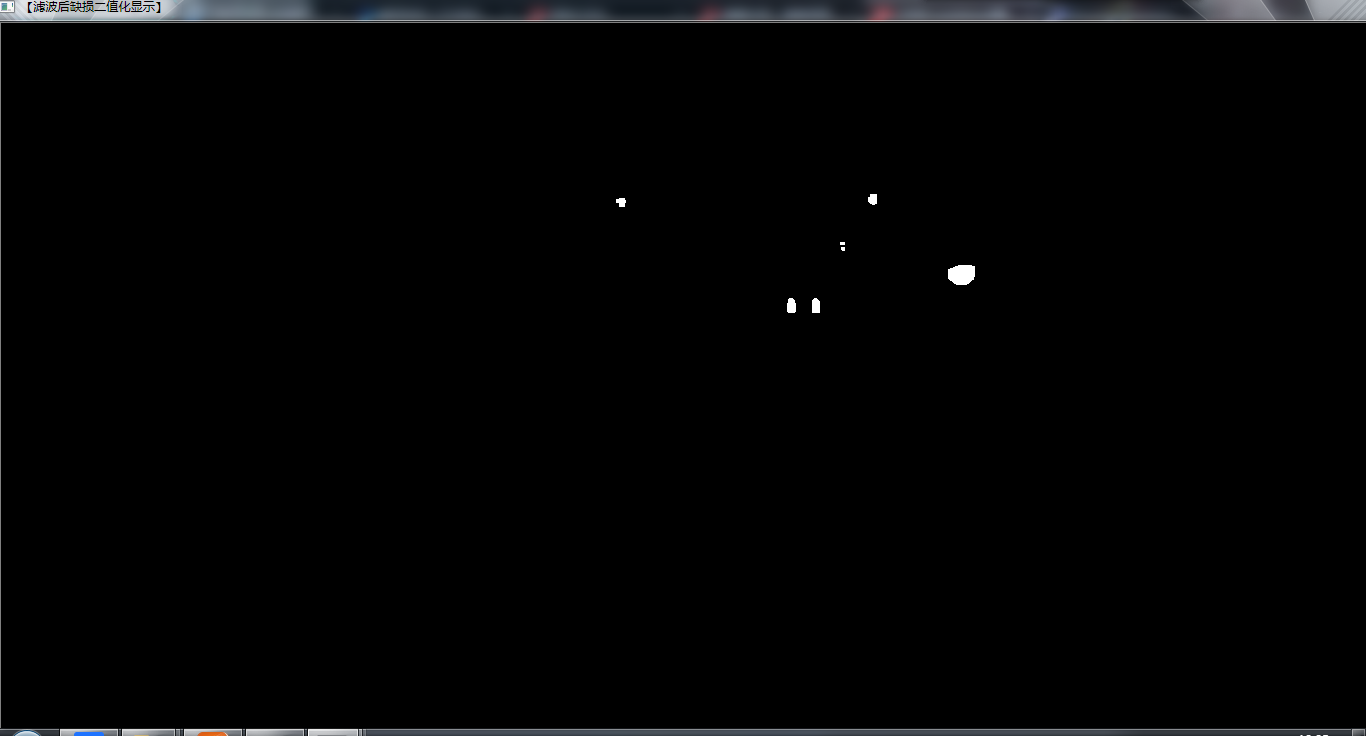

【滤波后图像】

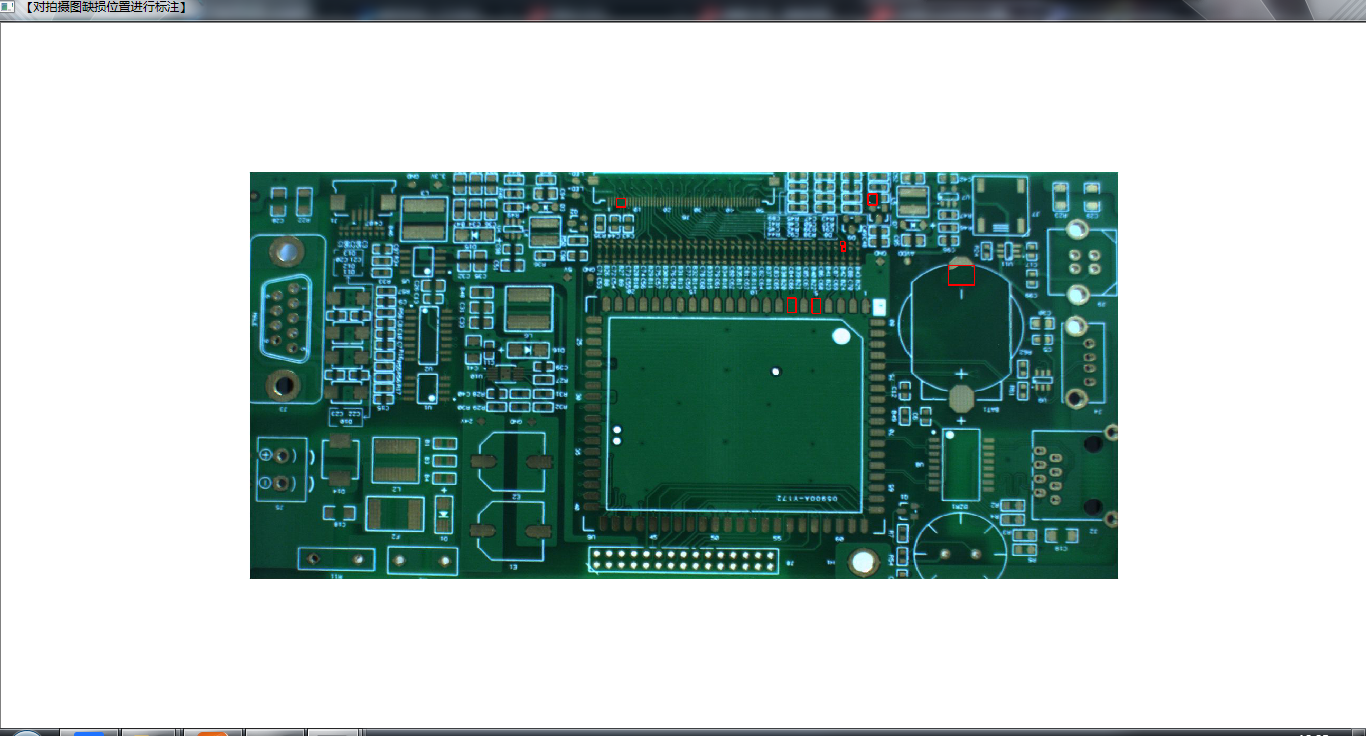

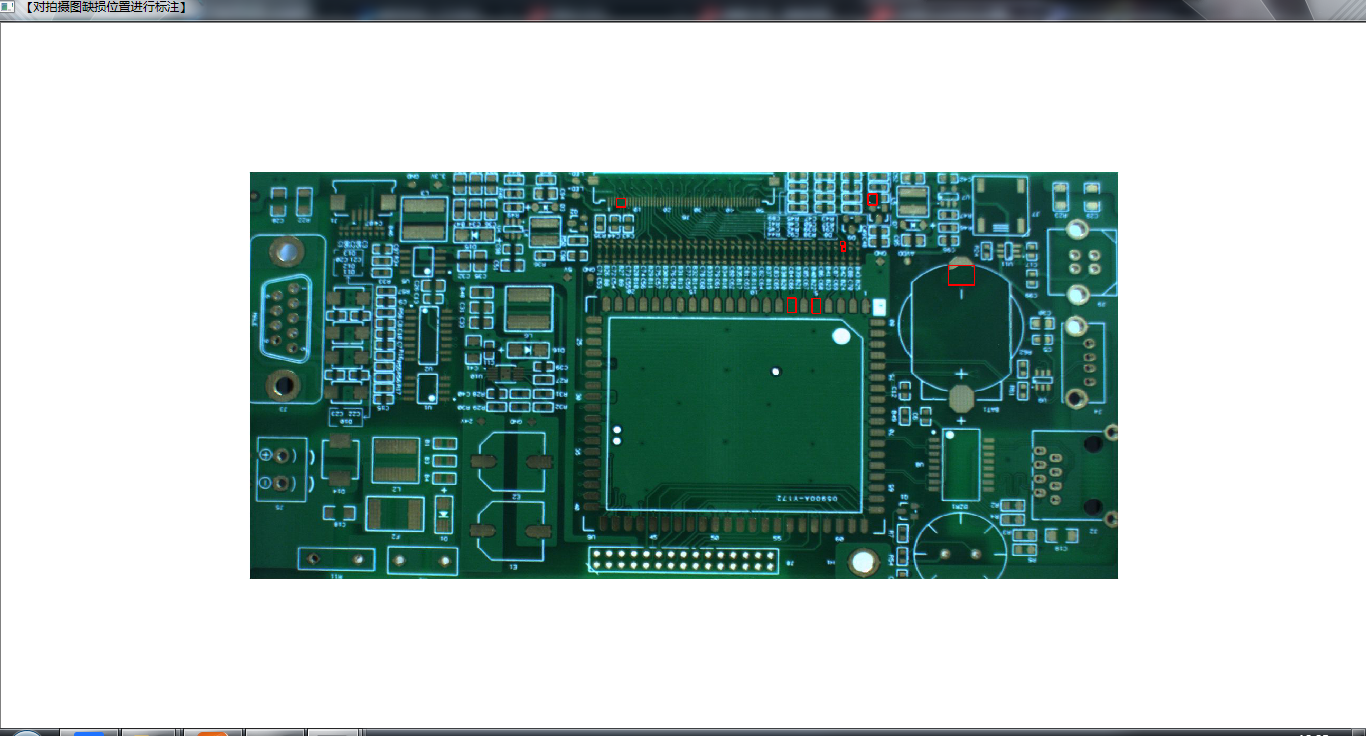

【缺损判断标记】(图上红 {MOD}矩形框) 程序中Wback是读入的一张纯白 {MOD}底板图片,这个底板分辨率和标准模板图片一致,为了在模板匹配后相减时防止检测图片因拍摄或放PCB板入卡槽时,位置的改变而处理的。 还有太多的东西需要学习,欢迎大神前辈们指教。

基本思想是通过定焦的工业摄像头,对放置于卡槽中的PCB进行拍摄并取ROI,与标准的PCB图片进行模板匹配,两者二值化后相减并中值滤波,在缺损处用红 {MOD}矩形标出,最后只命名输出缺损PCB图片。

为了给大家更好的演示,我将程序改为直接读取图片。

程序如下:

基本思想是通过定焦的工业摄像头,对放置于卡槽中的PCB进行拍摄并取ROI,与标准的PCB图片进行模板匹配,两者二值化后相减并中值滤波,在缺损处用红 {MOD}矩形标出,最后只命名输出缺损PCB图片。

为了给大家更好的演示,我将程序改为直接读取图片。

程序如下: (可能有些杂乱,本人水平还需提高)

/********************************************************************************/

/*

* Copyright(c)2016

* ALL rights reserved.

*

* file name: Lab_Identification_Program.cpp

* file description:

*

* Abstract:

* current version:2.0

* author: L T

* date: 2016.2.3

*

* replacement version:

* original author:

* date:

*/

/********************************************************************************/

#include(i); //获取第i行的首地址

for(int j = 0;j < colNumber;j++) //列循环

{

// ---------【开始处理每个像素】-------------

//data[j] = data[j]/div*div + div/2;

if(data[j]==255)//如果白 {MOD}

{

//imshow("【效果图】Canny边缘检测", grayImage);

imwrite("有问题的PCB.jpg",WbackClone1);

ConditionJudgment=0;

break;

}

// ----------【处理结束】---------------------

} //行处理结束

}

}

//------------------------------------------------------

// 主程序

//------------------------------------------------------

int main()

{

//CallCamera();//调用摄像头

namedWindow("【滤波前二值化效果】", 2);

namedWindow("【滤波后缺损二值化显示】", 2);

namedWindow("【对拍摄图缺损位置进行标注】", 2);

namedWindow("【彩 {MOD}ROI位置待判断图】", 2);

ReadPic();//读入图片

Binarization();//二值化

TempMatch();//模板匹配

subtract(srcImage,WbackClone,img_result1);//相减

subtract(WbackClone,srcImage,img_result2);

medianBlur(img_result1,img_result,3);//小噪点使用中值滤波 或 erode + dilate方案 3

medianBlur(img_result2,img_result2,3);

//GaussianBlur(img_result1,img_result,Size(3,3),0,0);//高斯滤波

//adaptiveThreshold(img, dst, 255, ADAPTIVE_THRESH_MEAN_C, THRESH_BINARY,3,5);

add(img_result,img_result2,img_result);//两幅互减图叠加

Mat ele = getStructuringElement(MORPH_RECT, Size(5,5));

dilate(img_result,img_result,ele);

Mat threshold_output;

vector<vector0, 0, 255 );

//rectangle( drawing, boundRect[i].tl(), boundRect[i].br(), color, 2, 8, 0 );//效果图上绘制矩形

rectangle( WbackClone1, boundRect[i].tl(), boundRect[i].br(), color, 2, 8, 0 );//原图上绘制矩形

}

DefectJudgment();//缺损判断

imshow( "【滤波前二值化效果】", img_result1 );

imshow( "【滤波后缺损二值化显示】", img_result );

imshow( "【对拍摄图缺损位置进行标注】", WbackClone1 );

waitKey(0);

}

效果如下图所示:

【完好无损的PCB】

【有缺损的PCB】(焊盘缺失或缺损)

【处理后未滤波的图片】

【滤波后图像】

【缺损判断标记】(图上红 {MOD}矩形框) 程序中Wback是读入的一张纯白 {MOD}底板图片,这个底板分辨率和标准模板图片一致,为了在模板匹配后相减时防止检测图片因拍摄或放PCB板入卡槽时,位置的改变而处理的。 还有太多的东西需要学习,欢迎大神前辈们指教。